10 Common A-Frame Mistakes That Can Damage Stone Slabs

-

A-frames are one of the most common tools used to store and transport stone slabs. When they’re used correctly, they keep material upright, organized, and protected. When they’re used incorrectly, they become one of the fastest ways to crack, chip, or ruin expensive stones.

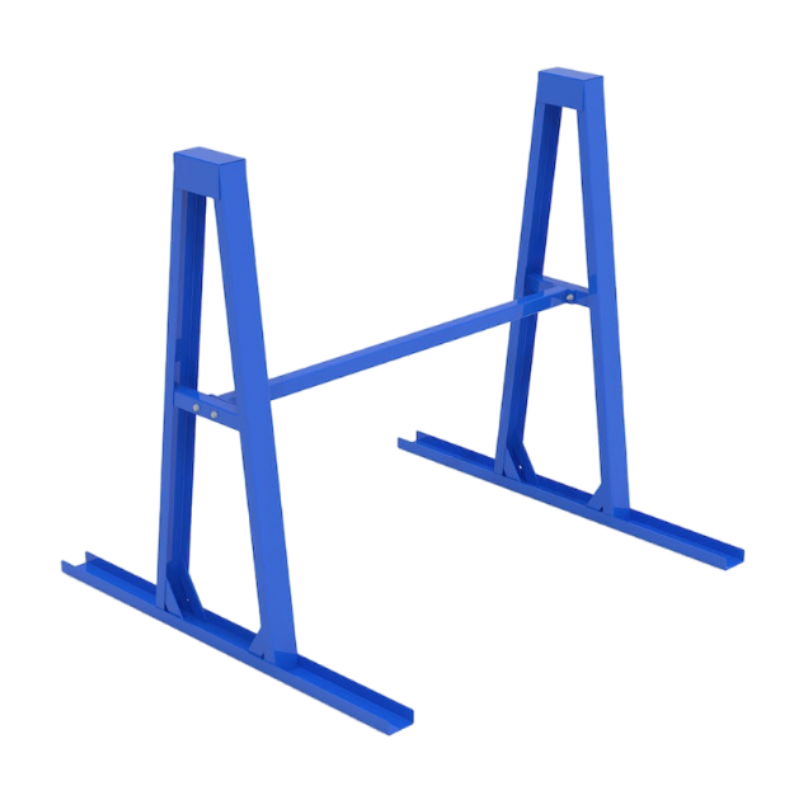

Tait Sales & Consulting, LLC supplies heavy-duty A-frames designed for real fabrication and transport conditions. Still, even the best A-frame can cause damage if basic mistakes are made. These problems show up in yards, shops, and on trucks every day, and most are preventable.

10 Common A-Frame Mistakes That Can Damage Stone Slabs

Mistake 1: Using Light-Duty or Improvised A-Frames

One of the biggest mistakes is using an A-frame that isn’t built for stone. Light-duty frames, homemade racks, or frames designed for other materials lack the strength and stability stone slabs require.

Stone slabs are heavy and unforgiving. If the frame flexes under load, weight shifts unevenly across the slab. That stress often leads to hairline cracks that may not show up immediately but fail later during fabrication or installation.

A proper A-frame must have heavy steel construction, rigid bracing, and stable feet. Anything less invites damage.

Mistake 2: No Rubber or Protective Padding

Bare metal contact is one of the fastest ways to damage stone. Slabs resting directly against steel uprights or bases can develop scratches, chips, or pressure points that weaken edges.

High-quality A-frames from Tait Sales include rubber-lined bases and uprights for a reason. Padding spreads the load evenly and protects polished surfaces from abrasion.

Skipping padding or using worn-out rubber is a costly shortcut. Once stone contacts metal, damage is only a matter of time.

Mistake 3: Overloading the A-Frame

Every A-frame has a capacity, and exceeding it puts both material and workers at risk. Overloading causes frames to lean, shift, or flex under weight. That movement transfers stress directly into the slabs.

Common signs of overloading include:

-

Frames bowing inward

-

Slabs pressing tightly against each other

-

Difficulty securing slabs properly

An overloaded frame may look stable at rest, but movement during forklift transport or truck loading can trigger sudden failure.

Loading fewer slabs per frame is always cheaper than replacing broken material.

Mistake 4: Improper Slab Spacing

Slabs stacked too closely together can rub, grind, or pinch each other. Even slight movement during transport can cause edge chipping or surface scratches when there’s no space between pieces.

A-frames are designed to hold slabs upright with proper spacing. That spacing allows:

-

Even weight distribution

-

Secure strapping

-

Reduced contact between slabs

Forcing extra slabs into a frame defeats its design and increases the chance of damage.

Mistake 5: Failing to Secure Slabs Correctly

An unsecured slab is a moving slab. One of the most dangerous mistakes is assuming gravity alone will hold a stone in place.

Without proper restraint systems, such as straps, locking bars, or anchor points, slabs can shift during:

-

Forklift movement

-

Yard repositioning

-

Truck transport

Once a slab starts moving, there’s almost no way to stop it safely. High-quality A-frames are designed to work with secure restraint systems. Using them correctly protects both the stone and the crew.

Mistake 6: Uneven Ground or Improper Placement

An A-frame is only as stable as the surface it sits on. Placing frames on uneven ground, soft gravel, or sloped surfaces causes imbalance.

That imbalance transfers uneven pressure into slabs and increases the chance of tipping. Over time, this can lead to stress fractures or sudden slab failure.

Frames should always be placed on solid, level ground. In yards, this often means concrete pads or reinforced surfaces designed to handle weight.

Mistake 7: Forklift Misuse

Forklift handling is one of the most common sources of slab damage. Incorrect fork spacing, uneven lifting, or sudden movements can shift slabs against the frame.

Common forklift-related mistakes include:

-

Lifting from only one side when both sides are required

-

Jerky starts and stops

-

Turning too sharply with a loaded frame

Heavy-duty A-frames from Tait Sales are built with forklift pockets designed for balanced lifting. Using those pockets correctly reduces stress on the frame and the slabs it carries.

Mistake 8: Mixing Slab Sizes and Weights Improperly

Not all slabs weigh the same. Mixing thin, lightweight material with thick, heavy slabs on the same A-frame can create uneven load distribution.

Heavier slabs should be positioned closest to the center and base of the frame. Lighter slabs should never be used to “fill gaps” between heavier pieces.

Ignoring weight balance increases pressure points and raises the risk of cracking during movement.

Mistake 9: Using the Wrong A-Frame Style

Not every A-frame is meant for every job. Single-sided frames, full A-frames, and transport A-frames each serve different purposes.

Using a storage frame for transport, or a transport frame for long-term yard storage, often leads to damage. Tait Sales offers multiple A-frame styles because workflow matters.

Choosing the correct frame for storage, movement, or transport is critical to slab protection.

Mistake 10: Poor Maintenance and Inspection

Even a high-quality A-frame needs regular inspection. Worn padding, bent uprights, cracked welds, or damaged straps compromise safety and slab protection.

Ignoring small issues allows them to turn into slab-breaking failures. A quick inspection before loading prevents expensive mistakes.

The Bottom Line

A-frames don’t damage stone, misuse does.

Most slab damage comes from avoidable mistakes:

-

Weak or improvised frames

-

No padding

-

Overloading

-

Poor spacing

-

Improper securing

-

Bad forklift handling

Tait Sales & Consulting, LLC supplies heavy-duty A-frames designed to handle the weight, movement, and daily abuse of stone fabrication environments. When used correctly, they protect material, improve workflow, and keep operations safe.

Stone slabs are too valuable to trust shortcuts. The right A-frame, used the right way, protects every slab from yard to jobsite.

-